ACME ROBOTIC POLISHING CELL WITH FANUC M710IB/45 ROBOT

Sold

ACME ROBOTIC POLISHING CELL WITH FANUC M710IB/45 ROBOT

Location:Almont, MI

Description

1-USED ACME ROBOTIC SANDING & POLISHING CELL

WITH FANUC M710IB/45 ROBOT AND RJ3iB CONTROLLER

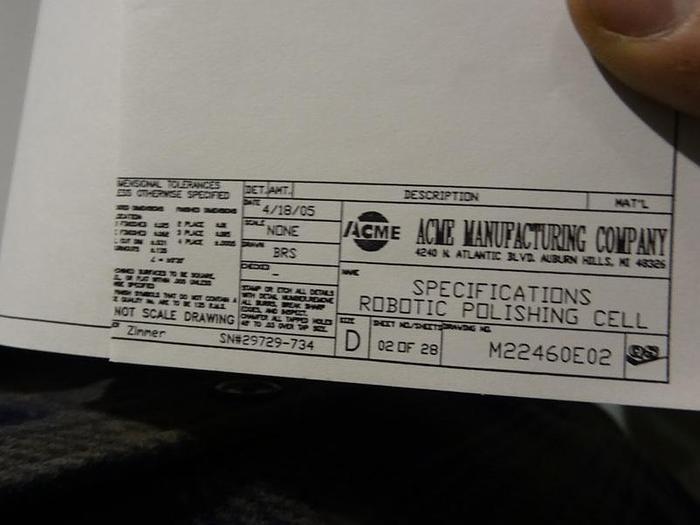

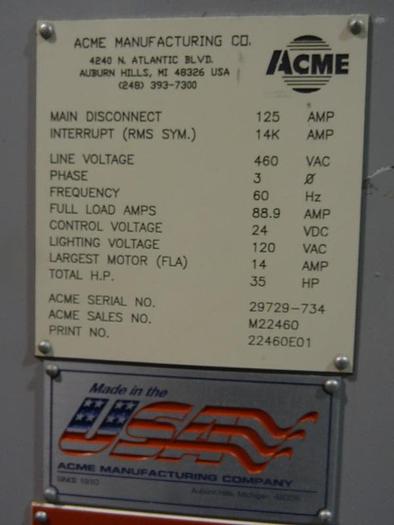

ACME SERIAL NUMBER 29729-734

ROBOT SERIAL NUMBER

DATE OF MFG. 2005 INSTALLED 10/2005

STK# 103536

==============================================================

SPECIFICATIONS WHILE OBTAINED FROM SOURCES DEEMED

RELIABLE ARE SUBJECT CHANGE WITHOUT NOTICE

AND TO VERIFICATION BY BUYER:

FULLY INTEGRATED ACME SANDING AND POLISHING CELL.

CELL IS FULLY ENCLOSED WITH FORKLIFT POCKETS FOR

EASY RELOCATION IN YOUR PLANT.

EQUIPPED WITH:

2 ACME SANDING STATIONS

2 ACME BUFFING POLISHING STATIONS

1 FANUC M710iB/45 6 AXIS CNC ROBOT WITH RJ3iB CONTROLLER

SPECS FOR ROBOT:

Robot Specifications

Axes: 6

Payload: 45.00kg

H-Reach: 1706.00mm

Repeatability: ±0.0700mm

Robot Mass: 530.00kg

Structure: Articulated

Mounting: Floor, Inverted, Angle

Robot Motion Speed

J1 160 °/s (2.79 rad/s)

J2 120 °/s (2.09 rad/s)

J3 150 °/s (2.62 rad/s)

J4 240 °/s (4.19 rad/s)

J5 240 °/s (4.19 rad/s)

J6 340 °/s (5.93 rad/s)

Robot Motion Range

J1 +320° - 350°

J2 ±260°

J3 ±420°

J4 ±540°

J5 ±250°

J6 ±720°

The FANUC R-J3iB uses advanced technology packaged in a proven, reliable and efficient controller design. Process capability and open architecture features provide intelligence to improve application and motion performance while simplifying system integration. The R-J3iB Controller incorporates the plug-in options concept, which allows flexibility for application specific configurations while maintaining a commonality for all users of the system.

Additionally, the R-J3iB supports both analog and digital input and output modules while also allowing the addition of optional process I/O boards, as necessary.

The controller cabinet has an operator panel that provides easy, intuitive buttons with flashing LEDs to indicate operating and cycle conditions. This helps simplify daily operations, such as for simple powering up, running a program, and powering down.

Connected to the controller cabinet via a cable (internally connecting to the controllers Main CPU board), the teach pendant enables the performance of operations away from the controller. The teach pendant can teach program data, test and debug programs, and adjust variables with its 16-line by 40-character LCD display, menu-driven function keys, keypad keys, and status LEDs. Additionally, this pendant can monitor and control I/O to control EOATs and displaying current information on the status or position of the robot.

Catalog Specifications:

Multi-processor architecture (separate motion and communication) with real time

Built-in Ethernet

100 Base-TX/10 Base-T with RJ-45 connector

Three RS-232 ports (one can be configured as RS-422)

Standard iPendant with available touch screen option

Part Numbers:

RJ3iB: A05B-2490-C372

FOB TRUCK, IMLAY CITY, MI 48444

THIS ITEM IS OFFERED FOR SALE SUBJECT TO PRIOR SALE AND

BUYER'S UNCONDITIONAL ACCEPTANCE OF SELLERS TERMS

AND CONDITIONS.

(586)752-0090

WWW.RABIND.COM

Specifications

| Manufacturer | ACME MANUFACTURING WITH FANUC ROBOT |

| Model | ACME POLISHIING CELL |

| Year | 2005 |

| Condition | Used |

| Serial Number | ACME SERIAL NUMBER 29729-734 FANUC ROBOT SERIAL NUMBER |

| Stock Number | 103536 |