Meile - Firebird Industrial FIP Pretreat Washer/Dryer System Direct To Garment Printing

Meile - Firebird Industrial FIP Pretreat Washer/Dryer System Direct To Garment Printing

$35,000 (USD)

Location:Pennsylvania

Available quantity:1

Description

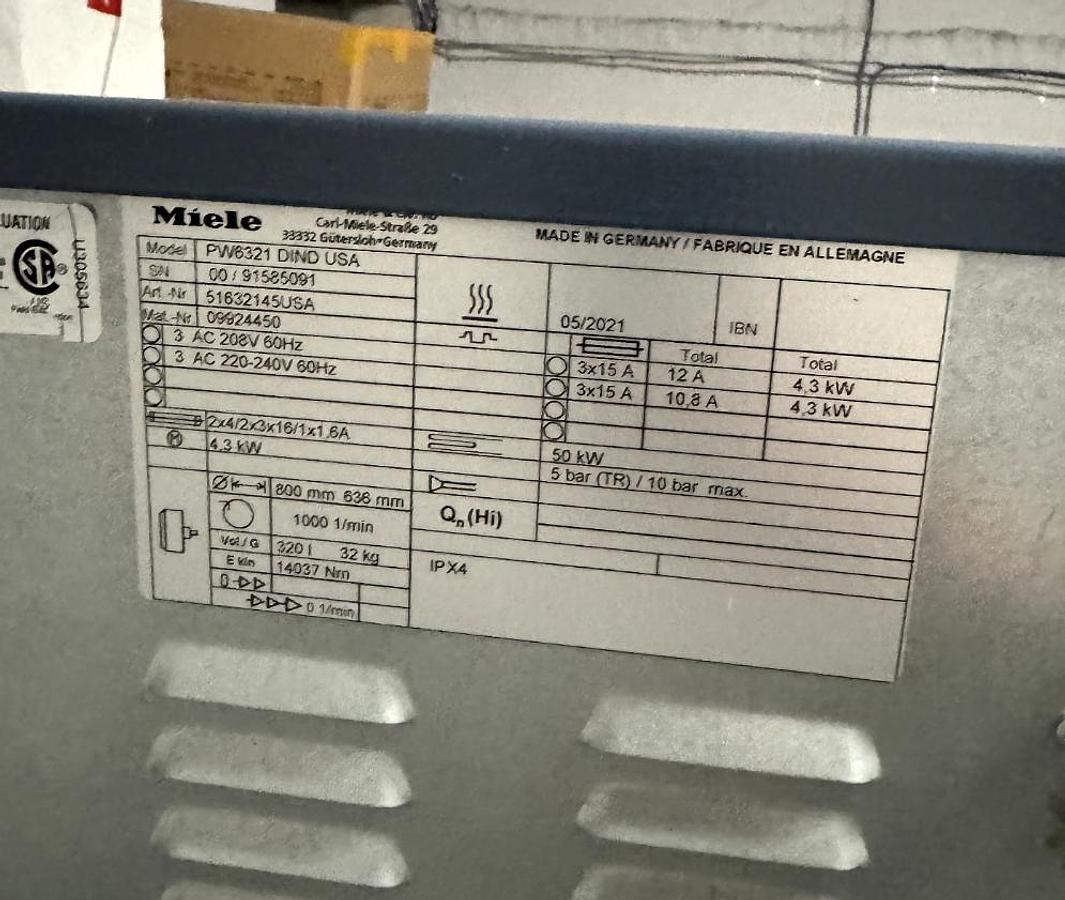

1-MEILE - Firebird Industrial FIP Pretreat Washer Model FB PW 6321 DINO for direct to garment printing

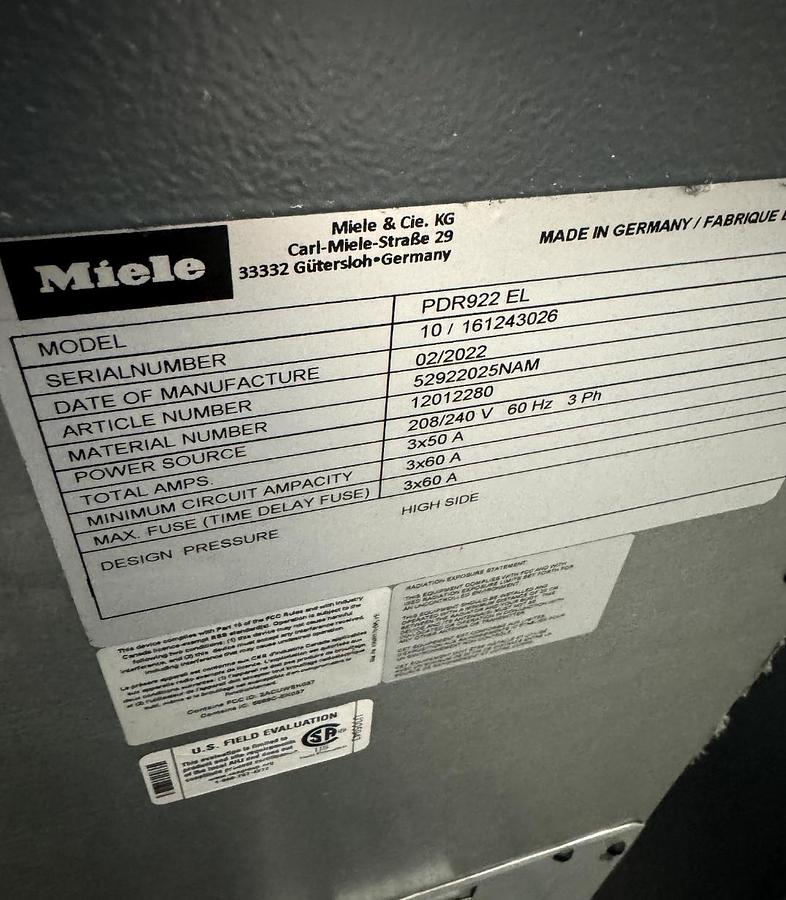

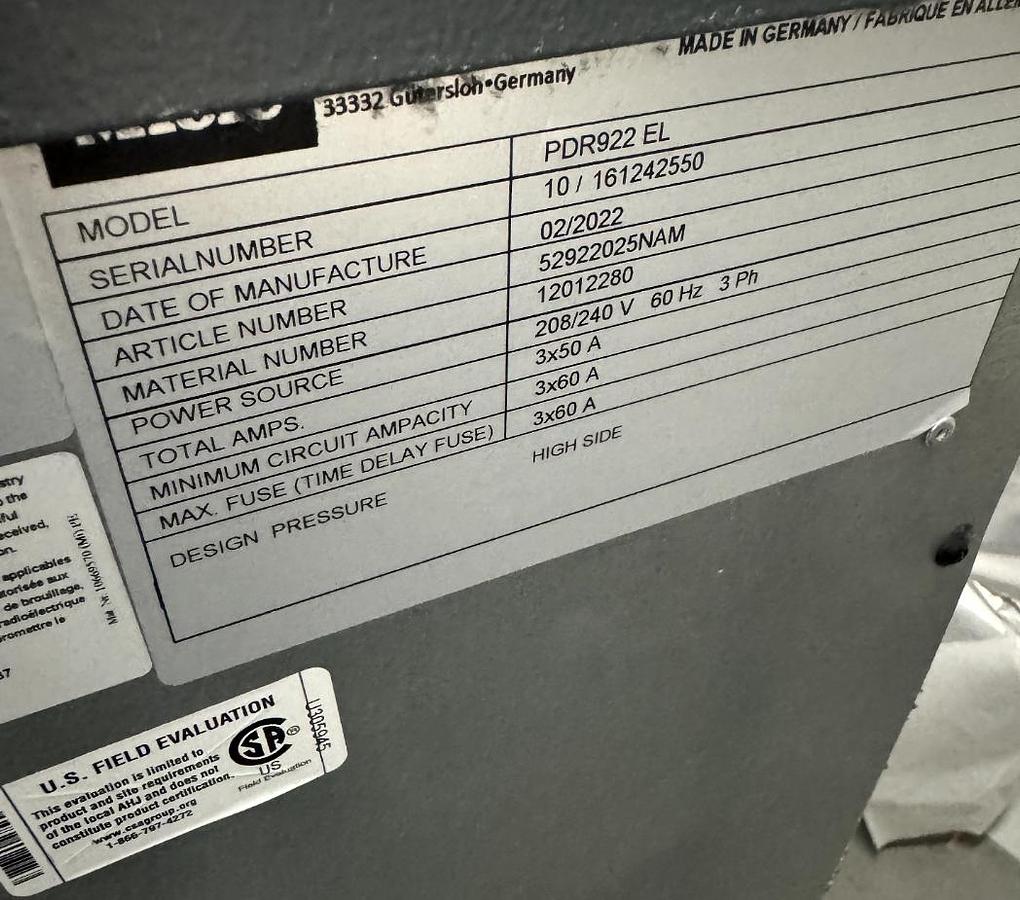

2-MEILE - MODELl PDR 922L FIP INDUSTRIAL DRYERS

DATE OF MFG. 2022

STK#105345

=============================

SPECIFICATIONS WHILE OBTAINED FROM SOURCES DEEMED RELIABLE ARE SUBJECT TO CHANGE WITHOUT NOTICE AND TO VERIFICATION BY BUYER:

1 washer + 2 dryers. Stop spraying and start using this system to pretreat your DTG items.

With the Firebird Industrial FIP Pretreat Washer/Dryer System you can bulk apply pretreat to your garments.

- One person operation can treat over 200 shirts per hour at half a penny per shirt to save money verses spraying!

- You are able to use your favorite brands and colors in the same batch

- Capable of doing 100 percent cotton, tri blends, and polyester

- Ability to print all over the garment

- Great quality prints anywhere on the garment

An FIP (FIREBIRD Industrial Processing™) washer and dryer system is a specialized pretreatment system for Direct-to-Garment (DTG) printing. It automates the pretreatment process, which is crucial for DTG printing to ensure ink adheres properly to garments. The system typically includes one washer-extractor and two dryers, allowing a single operator to pretreat a large number of garments efficiently.

Here's a more detailed breakdown:

- FIP System:

- FIREBIRD Ink, in partnership with Miele, developed the FIP system as an automated approach to pretreatment for DTG printing.

- Pretreatment Automation:

- The FIP system automates the process of applying pretreatment fluid to garments before printing. This eliminates the need for manual spraying, which can be messy and inconsistent.

- Washer-Extractor and Dryers:

- The system typically consists of a washer-extractor and two dryers. This configuration allows for continuous processing, with one machine handling washing and extraction, while the other two handle drying.

- Increased Efficiency:

- The FIP system significantly increases the speed and efficiency of the pretreatment process, allowing for pretreating hundreds of garments per hour.

- Reduced Labor Costs:

- By automating the pretreatment process, the FIP system can help reduce labor costs associated with manual pretreatment methods.

- Consistent Results:

- The automated system ensures consistent pretreatment, which is essential for high-quality DTG printing.

- Brands Supported:

- The system is designed to work with various garment brands, including Bella Canvas, Next Level, and Gildan.

THIS ITEM IS OFFERED FOR SALE SUBJECT TO PRIOR SALE AND BUYER'S UNCONDITIONAL ACCEPTANCE OF SELLERS TERMS AND CONDITIONS. RAB INDUSTRIES, INC.

Specifications

| Manufacturer | MEILE |

| Model | PW 6321 DINO USA |

| Year | 2022 |

| Condition | Used |

| Stock Number | 105345 |